LIMS System for Condition Monitoring Department

Digital Logbook

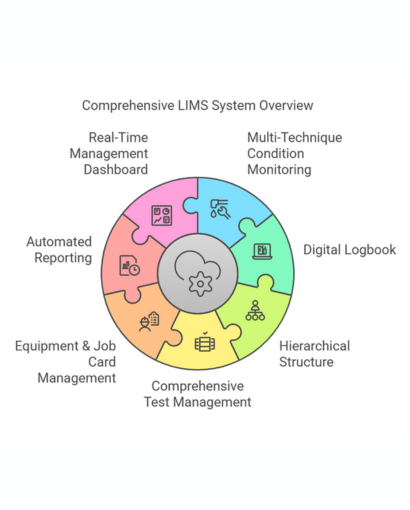

Overview

The LIMS (Laboratory Information Management System) is a cutting-edge digital logbook designed specifically for the Condition Monitoring Department. This platform enables technicians, engineers, and management to record, track, and analyze daily, weekly, and monthly test results for various condition monitoring techniques.

With real-time data access and automated reporting, LIMS enhances efficiency, accuracy, and decision-making in maintenance operations.

1. Multi-Technique Condition Monitoring

The LIMS system integrates five critical condition monitoring techniques, ensuring a comprehensive approach to predictive maintenance:

- Vibration Analysis

- Oil Analysis

- Thermography

- Non-Destructive Testing (NDT)

- Predictive Maintenance

Each technique has its own workflow, reporting structure, and role-based access, allowing departments to manage and analyze data effectively.

Digital Logbook for Easy Test Recording

- Users can log test data on a daily, weekly, or monthly basis.

- Automated data entry ensures consistency and reduces manual errors.

- Role-based access control allows SuperAdmin, Admin, and Employees to manage and view test records.

3. Hierarchical Structure for Plant & Area Management

- SuperAdmin can create and manage plants and areas for all techniques

- Admin can manage plants and areas specific to their assigned technique.

- Filter-based navigation for easy data retrieval based on technique, plant, and area.

4. Comprehensive Test Management

The LIMS system enables structured test creation and execution:

- Test Category & Methods: : Define test categories like Oil Analysis and Ferrography.

- Test Parameters: Configure parameter limits and measurement units.

- Manufacturer & Lubricant Database: Maintain lubricant specifications and set limits.

- Component Type & Sampling Locations: Track sample collection points for precise analysis.

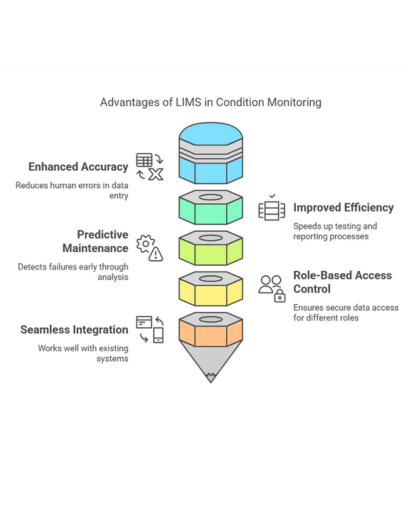

Benefits of LIMS for Condition Monitoring

- Enhanced Accuracy: Eliminates human errors with structured data input.

- Improved Efficiency: Faster test execution and automated report generation.

- Predictive Maintenance: Early failure detection with real-time analysis.

- Role-Based Access Control: Secure data access for admins, employees, and managers.

- Seamless Integration: Compatible with existing equipment databases and ERP systems.

Ready to Transform Your Condition Monitoring Process?

With LIMS, your department can shift from manual record-keeping to a fully automated digital logbook, ensuring efficiency, reliability, and predictive maintenance excellence.

Contact us today for a demo and see how LIMS can revolutionize your Condition Monitoring operations.